Heat exchanger is a device or equipment designed to exchange heat efficiently from one medium to another. The primary medium (Heating) and the secondary medium (Heated) can be Gas-Gas, Gas-Liquid, or Liquid-Liquid. Heat exchangers are also called heaters, coolers, or condensers depending on the expected end result of a process. In order to have this energy transfer several kinds of heat exchangers such as Shell & Tube, Plate & Frame, or Air Coolers are used.

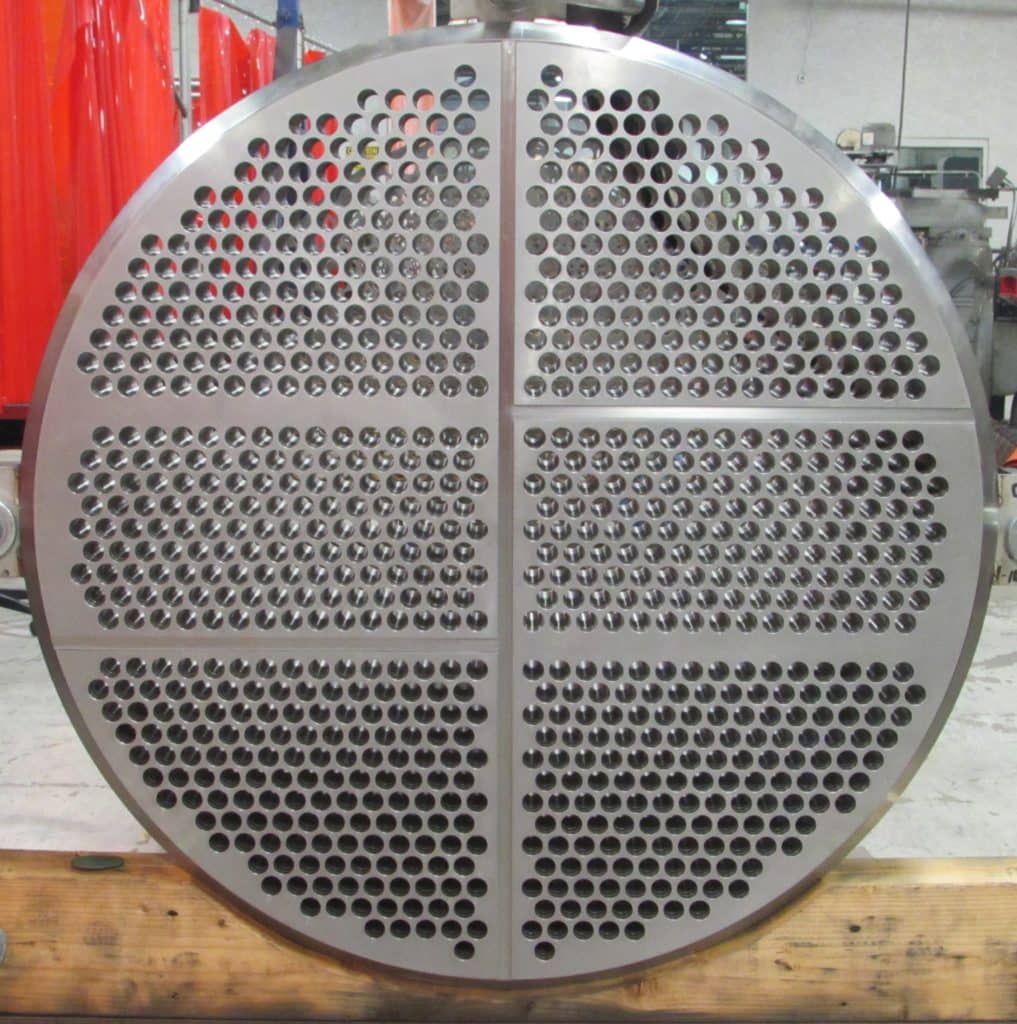

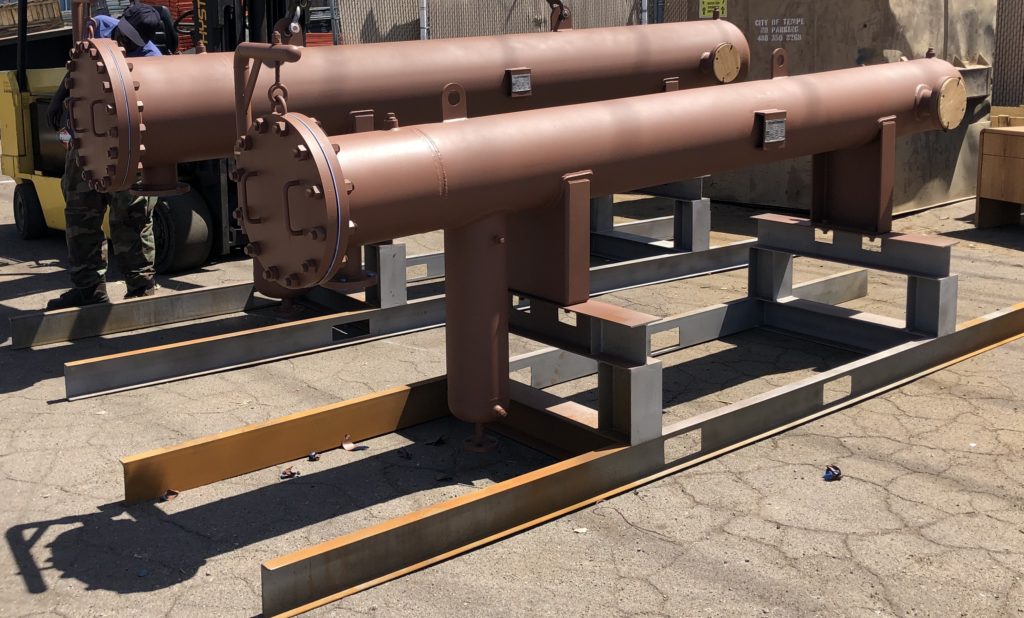

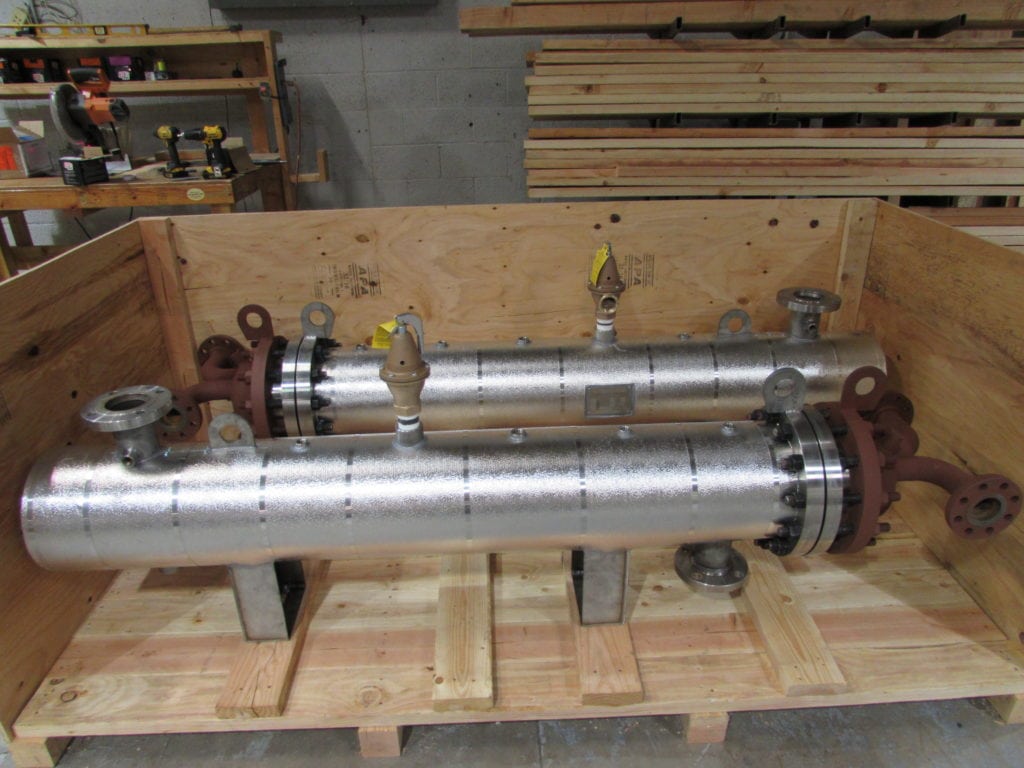

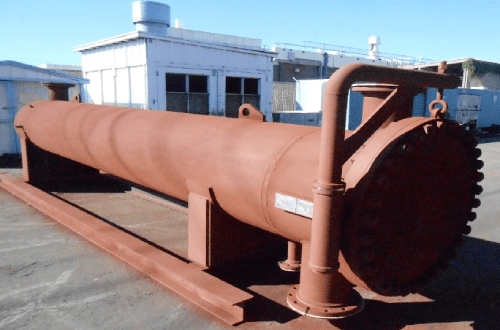

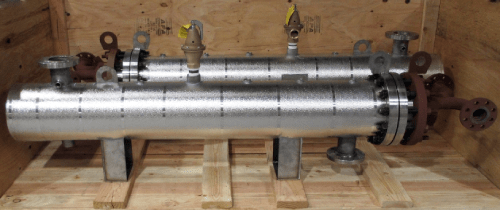

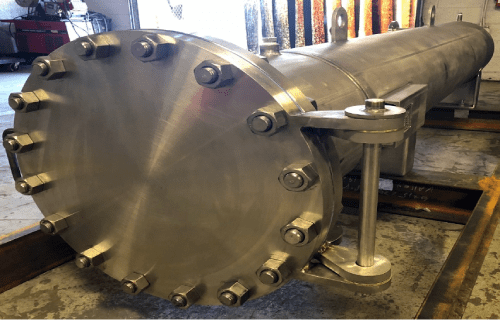

TruStop has over 20 years of experience in designing and fabricating Shell & Tube Heat exchangers & tube bundles per ASME codes and TEMA standards. Shell & Tube heat exchangers are further classified into TEMA types. TruStop Inc has experience designing and fabricating AES, BEU, NEU, NEN, and BEM TEMA type heat exchangers. Latest software tools such as the HTRI for highly optimized thermal design and COMPRESS for mechanical design are being used to design these heat exchanger units.

Appropriate selection and design of a heat exchanger could make big difference in process optimization and cost-saving for industries. TruStop Inc has always been able to assist and guide customers to select the right heat exchanger TEMA type for their application. Our heat exchanger units are often seen in service for veg oil heating, space heating, domestic water heating in hospitals, crude oil refineries, and much more.

Heat exchanger units are made of various exotic and non-exotic materials according to the service these are intended to be used for. We are well equipped and experienced in handling, machining, and welding a wide range of ASTM & ASME materials such as;

- Duplex Stainless Steel ( UNS 32205/31803)

- Super Duplex Stainless Steel ( UNS 32750)

- Hastelloy C276

- Inconel

- Incoloy

- Titanium

- PVQ Carbon Steel, SA 516 Gr 70, and other product forms.

- SS304/304L, S316/316L & SS 347.

- Aluminum

We have developed various WPS, PQR, and WPQ to weld exotic and non-exotic materials. All WPS & PQR are prepared to meet ASME Sec IX code requirements.

VIEW OUR HEAT EXCHANGER AND TUBE BUNDLE PHOTO GALLERY >> REQUEST QUOTE