TruStop has become a leader in the manufacturing industry, distinguishing itself from others through exceptional quality and customer service.

Our continuous investment in the development of a mix of machining technologies provides our clients a single source solution to optimally handle differences in equipment, complexity and run quantity.

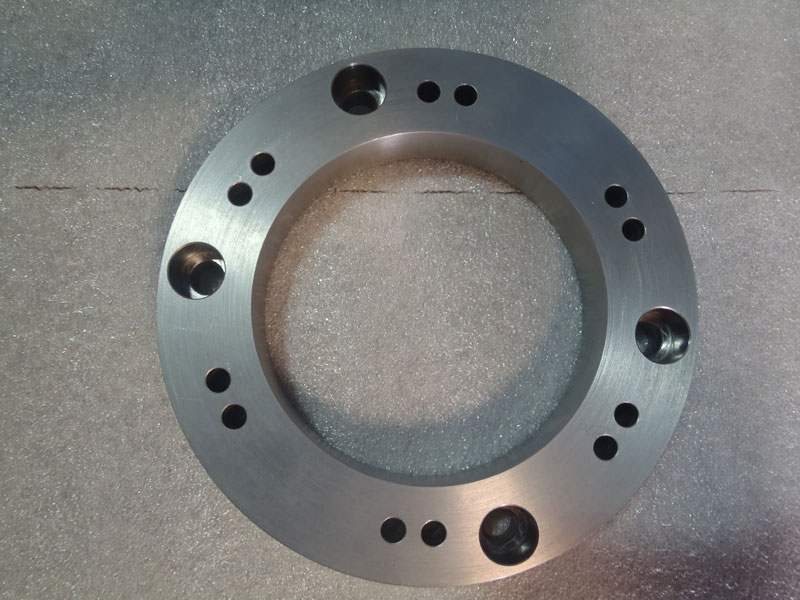

As a recognized leader TruStop is pleased to offer precision machining services suitable for a wide range of industries. All of our machining is performed utilizing state of the art equipment at our ISO 9001 accredited facility. Featuring 4- and 5-axis machine equipment our fleet includes multi-pallet horizontal machining centers, vertical machining centers, vertical lathes, horizontal lathes with live tooling and CNC controlled engine lathes. Our precision machine shop has a wide variety of milling and turning centers capable of manufacturing intricate parts that require extreme accuracy and consistency.

As a full service manufacturing company and through the utilization of precision milling and turning processes we can manipulate materials including aluminum, stainless steel, carbon steel, duplex, Hastelloy, titanium, plastics, brass, copper, Inconel and Monel to create custom components ranging from prototypes to small and high volume runs.

For more details about our cost-effective contract machining services, or our other design and manufacturing capabilities please see the table below or contact us directly.

View Our Precision Machined Parts Photo Gallery >> REQUEST QUOTE