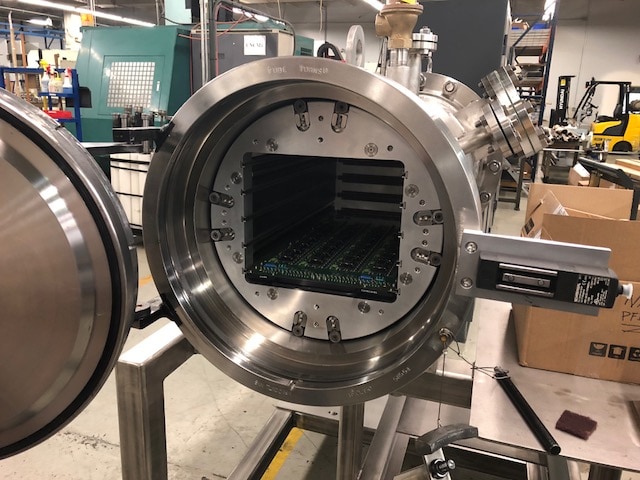

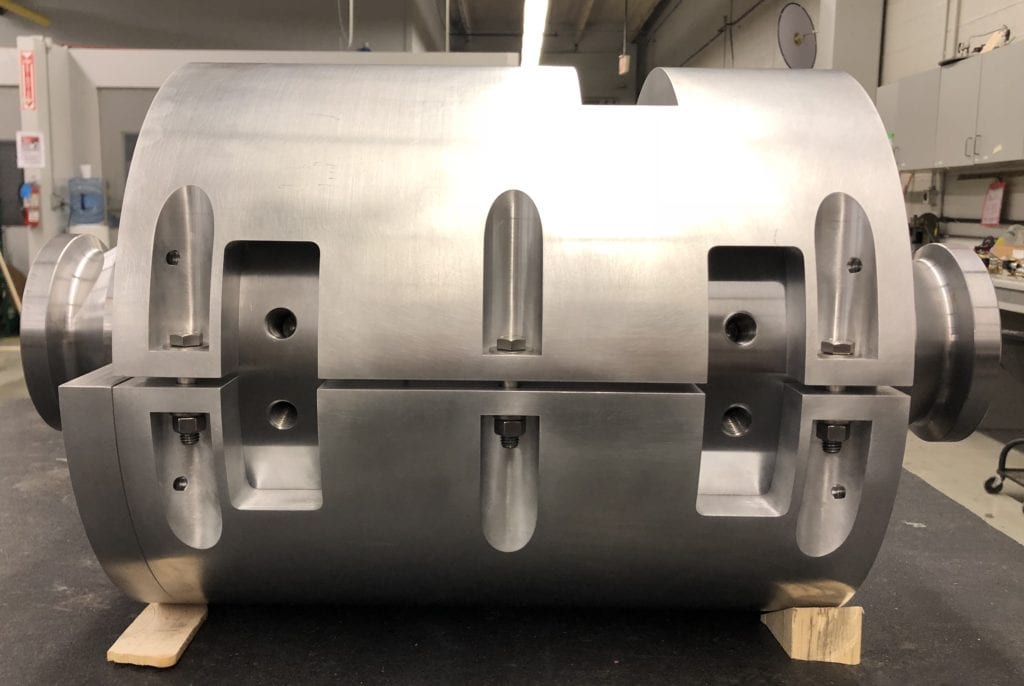

TruStop Inc offers the custom designing, manufacturing and testing of pressure vessels. We are in compliance with ASME Sect. VIII Div. 1, and TEMA, with CRN and hold ASME “U” Stamp certificate. We also hold National Board “R” stamp to repair U-Stamp certified pressure vessels. Pressure Vessels are designed and fabricated in both vertical and horizontal orientations, manufactured with carbon steel, stainless steel, nickel alloys, copper alloys, titanium, duplex 2205, duplex 32750, and titanium materials.

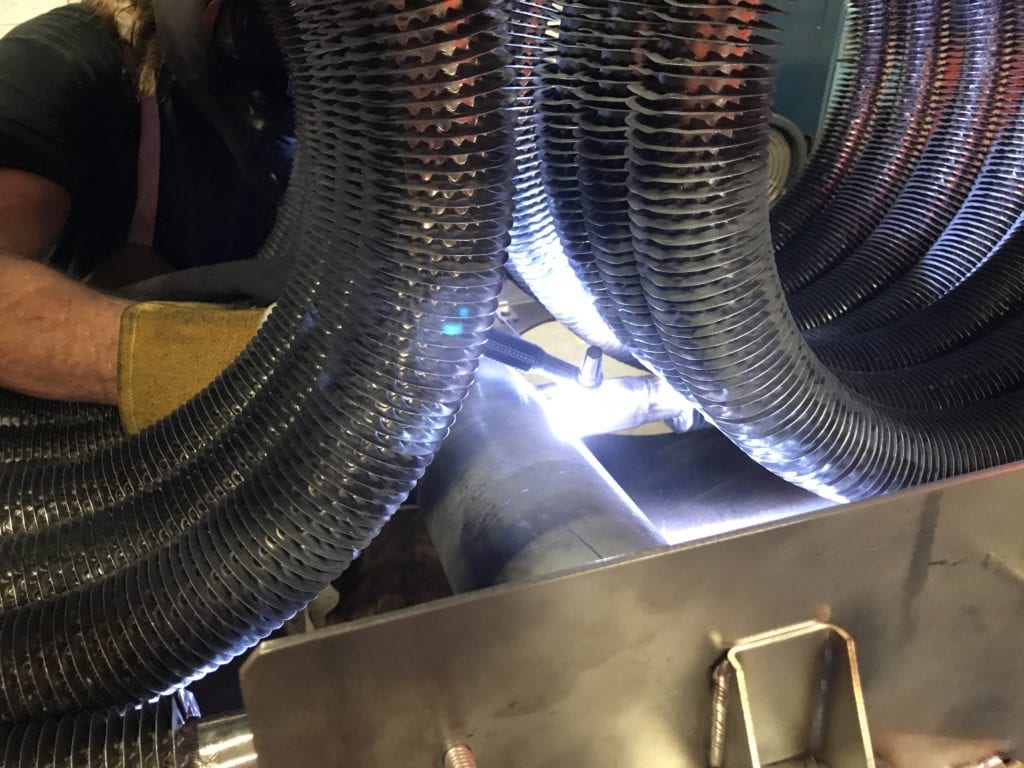

All our pressure vessels are hydro tested per ASME CODE and inspected during fabrication as required by Customer specification and ASME SEC IX which includes NDE (LPT, MPT, UT & Radiography). In addition to pressure vessels, we also provide a host of additional value-added services including CNC machining, fabrication, grinding, honing, sawing, welding, electro-mechanical assembly, design engineering, and repair services

Alert note: all Custom designing is certified by ASME Sect.VIII Div. 1 TEMA/CRN and not with AS9100/GWR

VIEW OUR ASME CODE PRESSURE VESSELS PHOTO GALLERY >> REQUEST QUOTE